JUNE 15, 2020. BY AMY WOLFE, AGSAFE.

After years of discussion, stakeholder meetings and financial review, the Cal/OSHA Standards Board finally passed the Outdoor Agricultural Operations During Hours of Darkness standard at its April 18, 2020 meeting. The concept, first discussed back in 2013, was initially raised when worker advocacy groups asserted that the industry was subverting compliance with heat illness prevention regulations by conducting work at night. In reality, certain segments of the agricultural industry had been working at night for decades, as it proved most beneficial for the crop. Regardless of the impetus, all of California’s agricultural industry now finds itself navigating a new safety standard for night work.

Lighting

At the cornerstone of the new standard is the need for an agricultural employer to ensure adequate lighting is available during the period between sunset and sunrise. The following table, taken directly from the standard, addresses the amount of area lighting that must be provided by the employer:

| Foot-candles | Lux | Areas or Tasks |

| 0.09-0.19 | 1-2 | Poultry harvesting or catching operations |

| 3 | 32.29 | Meeting area and meal/rest area |

| 5 | 53.82 | Outdoor agricultural operations except where otherwise specified in this table. Pathways leading to and around restrooms and drinking water. Inside restroom facilities. Storage areas accessed by employees. |

| 10 | 107.64 | Intermittently exposed or exposed point of operation equipment, covered under Group 8: Points of Operation and Other Hazardous Parts of Machinery. Operationally visible moving parts of machinery covered under Group 6: Power Transmission, Prime Movers, and Machine Parts of the General Industry Safety Orders. Task lighting for agricultural operations that involve the use of tools that can potentially cause cuts, lacerations, or punctures. |

| 20 | 215.30 | Task lighting for maintenance work on equipment |

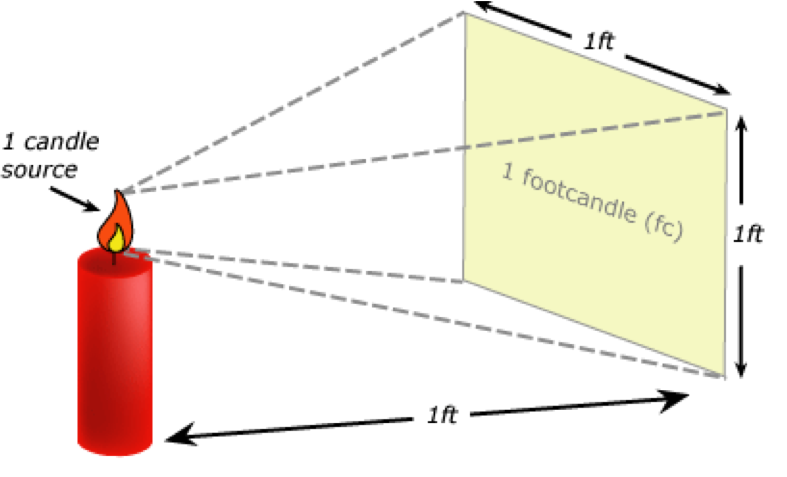

It is important to note that Cal/OSHA makes reference to foot-candles and lumens, both of which are units of measuring light. Foot candles refers to the amount of light produced from a source at a distance of one foot. In simpler terms, it is the distance unit of measurement from the source of light. However, lumens measures brightness and from a practical perspective, is the unit of measurement found on lightbulbs. As employers look to address compliance, they will find that most lighting source measurements will be provided to them in lumens.

Foot candles refers to the amount of light produced from a source at a distance of one foot. (Source: AgSafe)

Foot candles refers to the amount of light produced from a source at a distance of one foot. (Source: AgSafe)

Another essential distinguishing factor in the standard is that area light will be measured 30” off the ground or surface on which the employee walks. This means that employers must have the capability of measuring the amount of light relative to where employees are working, so as to ensure the aforementioned table of task lighting requirements is being met. A light meter is the most common tool used to accurately measure the amount of light being produced.

In correspondence with Cal/OSHA earlier in the year, the following details were provided regarding the types of light meters enforcement staff would use in the field when conducting investigations:

- Light meter brands: Davis, SPER or Extech

- Meter range (difference between lowest level and highest level it can record): max 50,000 Lux to 400,000 Lux

- Resolution: 0.1Fc / 1Lux

- Basic Accuracy: ±5%

Employers are highly encouraged to purchase light meters in alignment with these specifications so as to ensure consistency with those who will be enforcing the regulation.

Employers should purchase a light meter to take accurate readings in real time, assuring their sources of lighting meet the task lighting requirements. Extech, Davis and SPER are the three brands of light meters Cal/OSHA staff intend to use when conducting enforcement activity. (Source: Grainger)

Employers should purchase a light meter to take accurate readings in real time, assuring their sources of lighting meet the task lighting requirements. Extech, Davis and SPER are the three brands of light meters Cal/OSHA staff intend to use when conducting enforcement activity. (Source: Grainger)

The last two items of note relative to lighting is that area lighting must be set up in a manner that minimizes glare to workers. This furthers the need for employers to test lighting options prior to implementation to ensure that brightness issues are addressed, along with the potential for glare, based on the work being done. The other lighting requirement is that the employer must provide hands-free personal lighting, along with area lighting, as needed to ensure the task lighting requirements. Ultimately, the expectation is that all work to be conducted at night is well lit, whether through area lighting, personal lighting or a combination of the two.

Additional Standard Requirements

Lighting is not the only requirement of this new standard. Employers will be required to train workers at the start of each shift, reviewing:

- Location of restrooms and how to safely access them in the dark

- Location of drinking water and how to safely access it in the dark

- Location of designated break areas and how to safely access it in the dark

- Location of bodies of water and other potential hazards, including high traffic areas

As with any training, this must be documented, and records appropriately maintained. In addition, employers must provide at no cost and require employees to wear Class 2 high visibility safety clothing. This could be a vest or jacket; the type of clothing is at the discretion of the employer.

Lastly, while the standard does not specifically state as such, Cal/OSHA has an expectation based on the Injury and Illness Prevention Program regulation, that employers document the specific program elements that are unique when working at night. In simplest terms, an employer needs to evaluate their operating procedures and make note of how work is done differently at night so as to ensure the health and safety of workers. This includes identifying new hazards, which are addressed during employee training, as well as considering how emergency response procedures would unfold outside of “normal” business hours. Ultimately, as the agricultural industry continues to use the hours between sunset and sunrise as a viable time to work, it will soon be incumbent upon us to comply with a standard designed to ensure continued workplace safety.

For more information about worker safety, human resources, labor relations, pesticide safety or food safety issues, please visit agsafe.org, call (209) 526-4400 or email safeinfo@agsafe.org. AgSafe is a 501c3 nonprofit providing training, education, outreach and tools in the areas of safety, labor relations, food safety and human resources for the food and farming industries. Since 1991, AgSafe has educated over 85,000 employers, supervisors, and workers about these critical issues.

Featured Image: Photo by Stephanie Russo

Have something interesting to say? Consider writing a guest blog article!

To subscribe to the Coffee Shop Blog, send an email to stephanie@lodiwine.com with the subject “blog subscribe.”

To join the Lodi Growers email list, send an email to stephanie@lodiwine.com with the subject “grower email subscribe.”

To receive Lodi Grower news and event promotions by mail, send your contact information to stephanie@lodiwine.com or call 209.367.4727.

For more information on the wines of Lodi, visit the Lodi Winegrape Commission’s consumer website, lodiwine.com.