SEPTEMBER 16, 2019. BY AMY WOLFE, AGSAFE.

Each year, Cal/OSHA releases enforcement trends for all industries and agriculture is no exception. From October 2017 through September 2018, the agency stayed busy tracking the occupational injuries and illnesses of our state’s farmworkers. For this most recent year of data available, the industries ten most common violations resulted in a total of 345 citations totaling $1,154,682 in fines. On average, agricultural employers paid $3,347 per citation to Cal/OSHA alone, never mind the added expense of appeal and subsequent increased employment costs, like workers’ compensation insurance. Note that the order is based on the total number of citations issued, not the monetary impact of those citations.

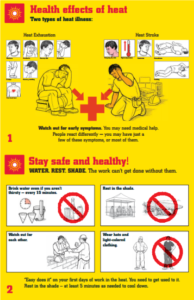

#1: Heat Illness Prevention

California Code of Regulations (CCR), Title 8, Section 3395

Violations: 130

Total fines: $403,762

Since its inception, the heat illness prevention standard has historically been one of the ten most frequently violated standards by the agricultural industry. While we have made meaningful strides in improving our day-to-day operations, we continue to be challenged by the paperwork requirements of the regulation. As noted by David Hornung, Cal/OSHA Heat and Agricultural Program Coordinator, one of the industry’s remaining challenges is failing to have a copy of the company’s heat illness prevention plan available in the field. It is critical that this document be available and easily accessible to all employees, not to mention Cal/OSHA enforcement staff, when requested.

As a reminder, the core tenants of the standard include the following:

- Develop a company-specific heat illness prevention program that is in writing, with a copy available to employees in the location where they are working and available for inspection.

- The plan needs to include and/or address the following:

- Provision of Water

- Access to Shade

- High Heat Procedures

- Rest Periods

- Worker Training

- Supervisor Training

- Observation and Response Requirement

- Emergency Medical Services

- Provision for First Aid Training

- Acclimatization

PHOTO – Heat Illness Health Impact. Click on photo to enlarge. (Source: Cal/OSHA)

PHOTO – Heat Illness Health Impact. Click on photo to enlarge. (Source: Cal/OSHA)

Growers, packers, shippers, and processors still unclear about how to address compliance with the heat illness prevention standard are encouraged to reach out to AgSafe or your commodity trade association for assistance on how to implement this regulation.

#2: Injury and Illness Prevention

California Code of Regulations (CCR), Title 8, Section 3203

Violations: 90

Total fines: $261,480

When implemented in 1991, the Injury and Illness Prevention Program (IIPP) standard was the first of its kind in the nation. Even today, nearly 30 years later, it stands out as the preeminent regulation specific to creating the foundation of an organization’s occupational safety and health program. The IIPP includes eight required elements:

- Identify responsible person(s) for program administration.

- Ensure employee compliance with safe and healthy work practices.

- System for communication with employees relative to workplace hazards.

- Procedures to identify and evaluate workplace hazards.

- Investigate injuries and illnesses.

- Procedures for correcting unsafe/unhealthy conditions, work practices and procedures.

- Provide employee safety training.

- Ensure thorough recordkeeping and document retention relative to the implementation of the safety program.

PHOTO – Tailgate Training (Source: AgSafe)

PHOTO – Tailgate Training (Source: AgSafe)

The team at Cal/OSHA works from the premise that all employers have an IIPP as the basis for their company workplace safety program. All other programs, such as heat illness prevention, hazard communications, lock out/tag out – to name a few – build upon the core tenants in the IIPP. As such, it is essential that agricultural employers remedy deficiencies that may exist in complying with this standard as they work to improve overall occupational safety and health.

#3: Field Sanitation

California Code of Regulations (CCR), Title 8, Section 3457

Violations: 47

Total fines: $30,440

The third most frequently citated regulation is specific to the provision of clean, usable field restrooms, handwashing facilities and drinking water. The standard overall is relatively straightforward and as an industry, our compliance challenges stem primarily from cleanliness. The bottom line is that employers need to invest to time and resources to ensure field restrooms are kept clean, well-stocked and with ample potable drinking water.

As a refresher, the standard requires the following:

- Provide potable drinking water, toilets and hand washing facilities to hand-laborers in the field.

- Ensure there is one toilet and hand washing facility for every 20 employees of each gender, located within a quarter mile walk.

- Facilities must be maintained properly, clean and in good working order.

PHOTO – Field Sanitation (Source: AgSafe)

PHOTO – Field Sanitation (Source: AgSafe)

#4: Operation of Agricultural Equipment

California Code of Regulations (CCR), Title 8, Section 3441

Violations: 21

Total fines: $173,925

Fourth on the list of most-common violations for the agricultural industry has to do with the operation of equipment. This standard is incredibly broad in nature, relative to the types of machines that fall within its scope. In addition, it is an area of our businesses that many employers take for granted. We often take employees at their word that they have been properly trained in the safe use of equipment. In addition, it is common practice to not provide the requisite on-going training or insist that workers follow the company protocol relative to safe equipment operation.

Unlike the preceding standard, this is one that is directly correlated to our day-to-day activities and is exacerbated by complacency, production pressures and labor shortages. Also, unlike the previous standard, failure to comply with this regulation leads to serious injuries and fatalities and as a result, should never be taken lightly. In simplest terms, the regulation states the following:

- An employee shall be instructed in the safe operation and servicing of all equipment before that employee is assigned to operate the equipment.

- Training shall continue annually.

- Examples of this type of equipment include tractors, forklifts, ATVs, UTVs, and other custom and specialty equipment.

- A compliant program will include:

- What personal protective equipment (PPE) is required to operate the equipment

- Pre-Inspection Checklist

- Use of seat belts

- Lock Out/Tag Out/Block Out Procedures

- Documentation protocol

The remainder of the Top 10 list is as follows:

- #5: Reporting a Work-Connected Fatality and Serious Injury (CCR, Title 8, Section 342) – Violations: 13, Total fines: $49,750

- #6: First Aid Kits (CCR, Title 8, Section 3439) – Violations: 13, Total fines: $5,105

- #7: Lock Out/Tag Out/Block Out (CCR, Title 8, Section 3314) – Violations: 10, Total fines: $81,295

- #8: Industrial Trucks (CCR, Title 8, Section 3650) – Violations: 10, Total fines: $62,025

- #9: Machinery and Equipment (CCR, Title 8, Section 3328) – Violations: 6, Total fines: $43,450

- #10: Portable Ladders (CCR, Title 8, Section 3276) – Violations: 5, Total fines: $43,450

Given the litany of regulatory issues facing agricultural employers today, it is important to maintain perspective with helpful insight into the areas where we struggle the most. Use this information to evaluate your own operation, prioritize how to make improvements and consider where your greatest gaps exist.

For more information about worker safety, human resources, labor relations, pesticide safety or food safety issues, please visit www.agsafe.org, call (209) 526-4400 or email safeinfo@agsafe.org. AgSafe is a 501c3 nonprofit providing training, education, outreach and tools in the areas of safety, labor relations, food safety and human resources for the food and farming industries. Since 1991, AgSafe has educated over 85,000 employers, supervisors, and workers about these critical issues.

Have something interesting to say? Consider writing a guest blog article!

To subscribe to the Coffee Shop Blog, send an email to stephanie@lodiwine.com with the subject “blog subscribe.”

To join the Lodi Growers email list, send an email to stephanie@lodiwine.com with the subject “grower email subscribe.”

To receive Lodi Grower news and event promotions by mail, send your contact information to stephanie@lodiwine.com or call 209.367.4727.

For more information on the wines of Lodi, visit the Lodi Winegrape Commission’s consumer website, lodiwine.com.